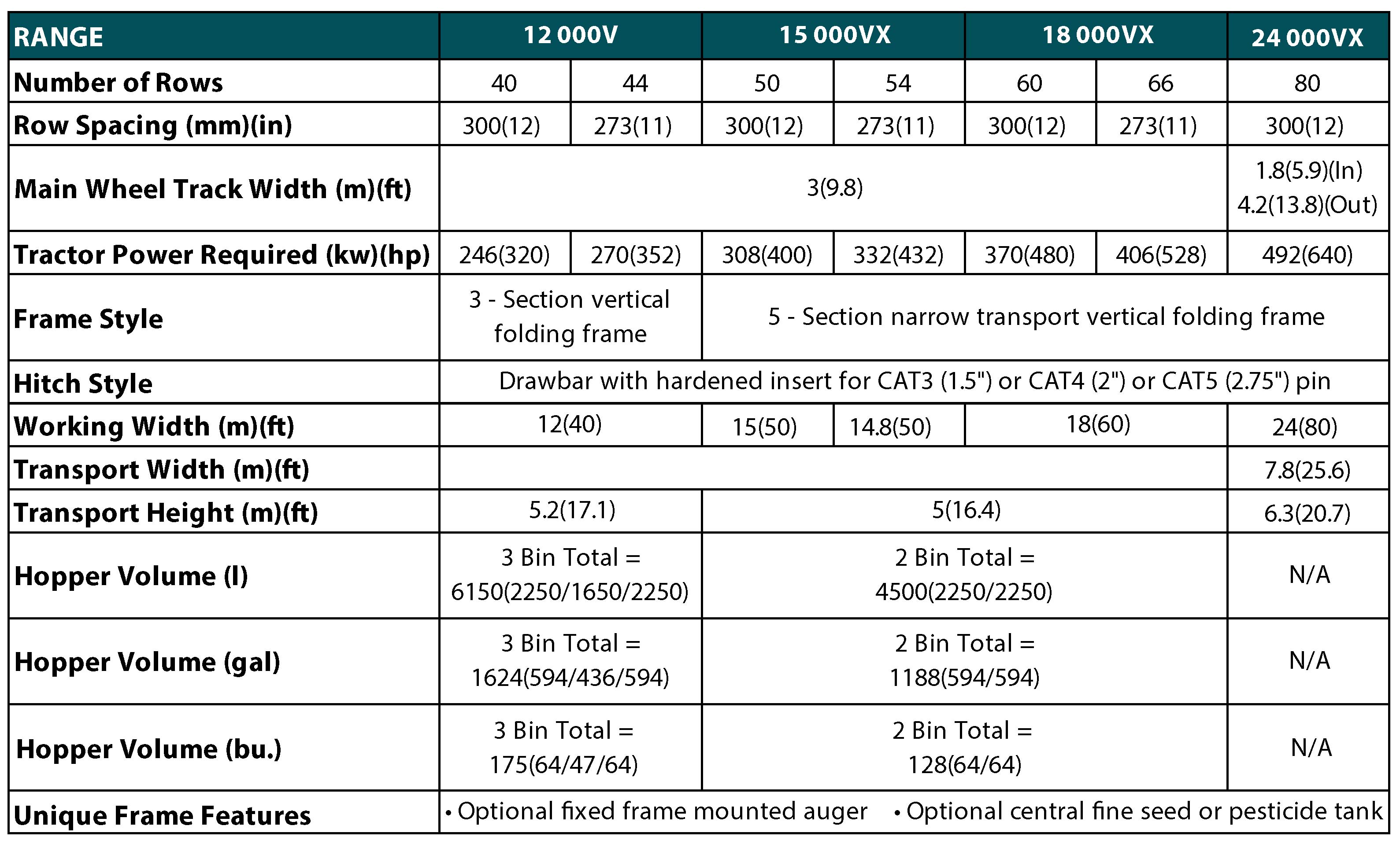

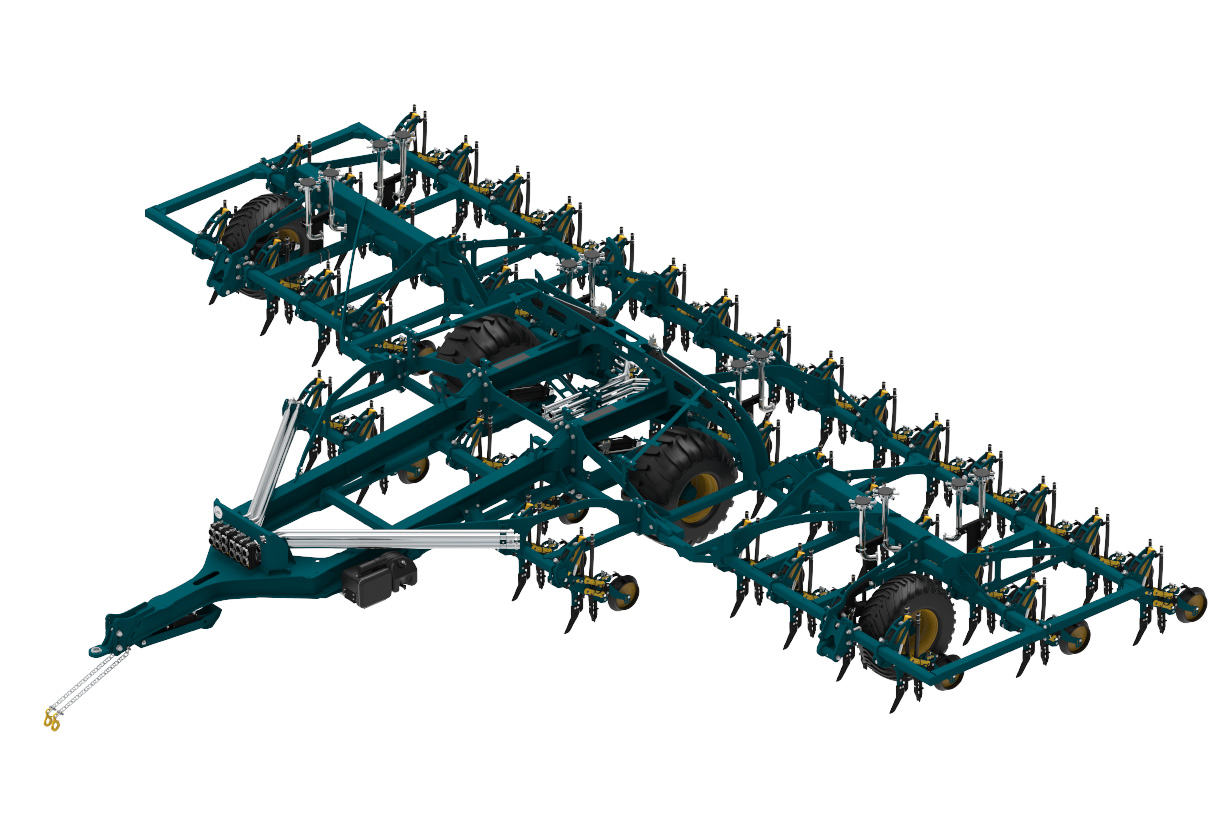

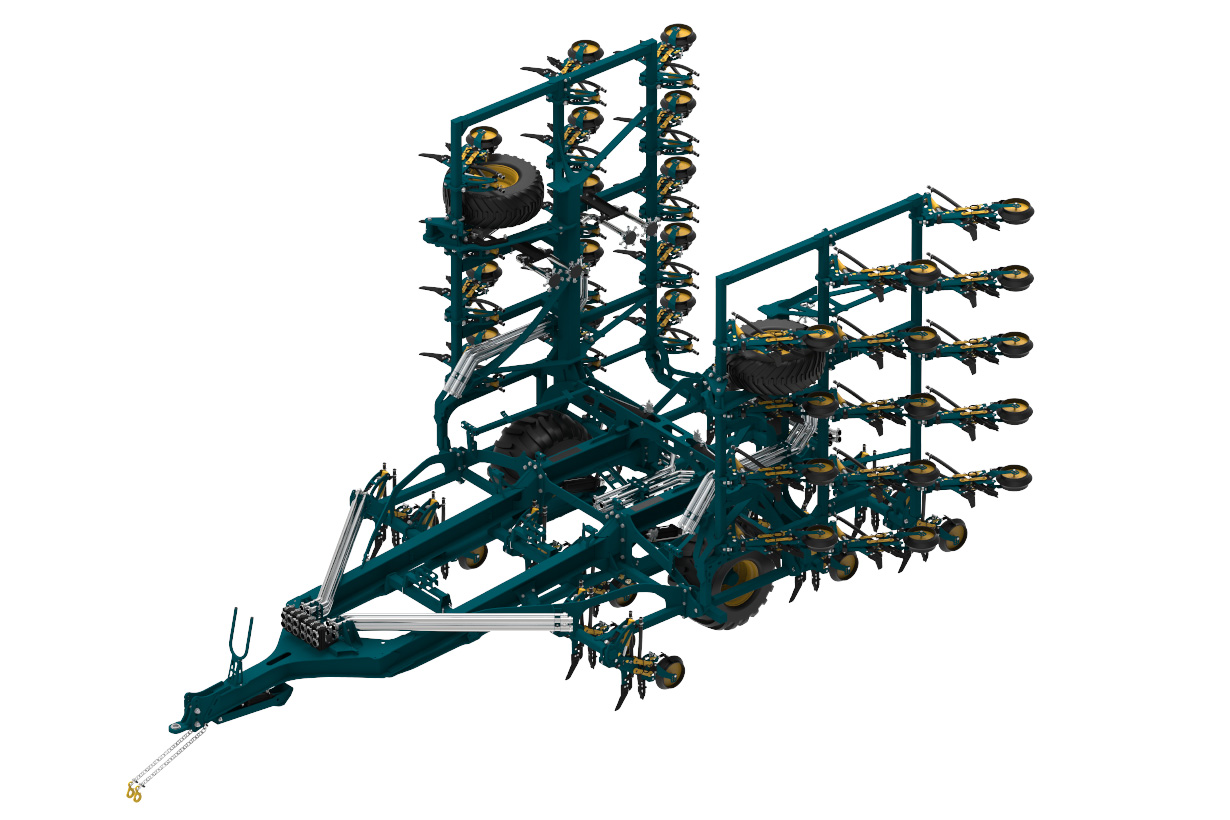

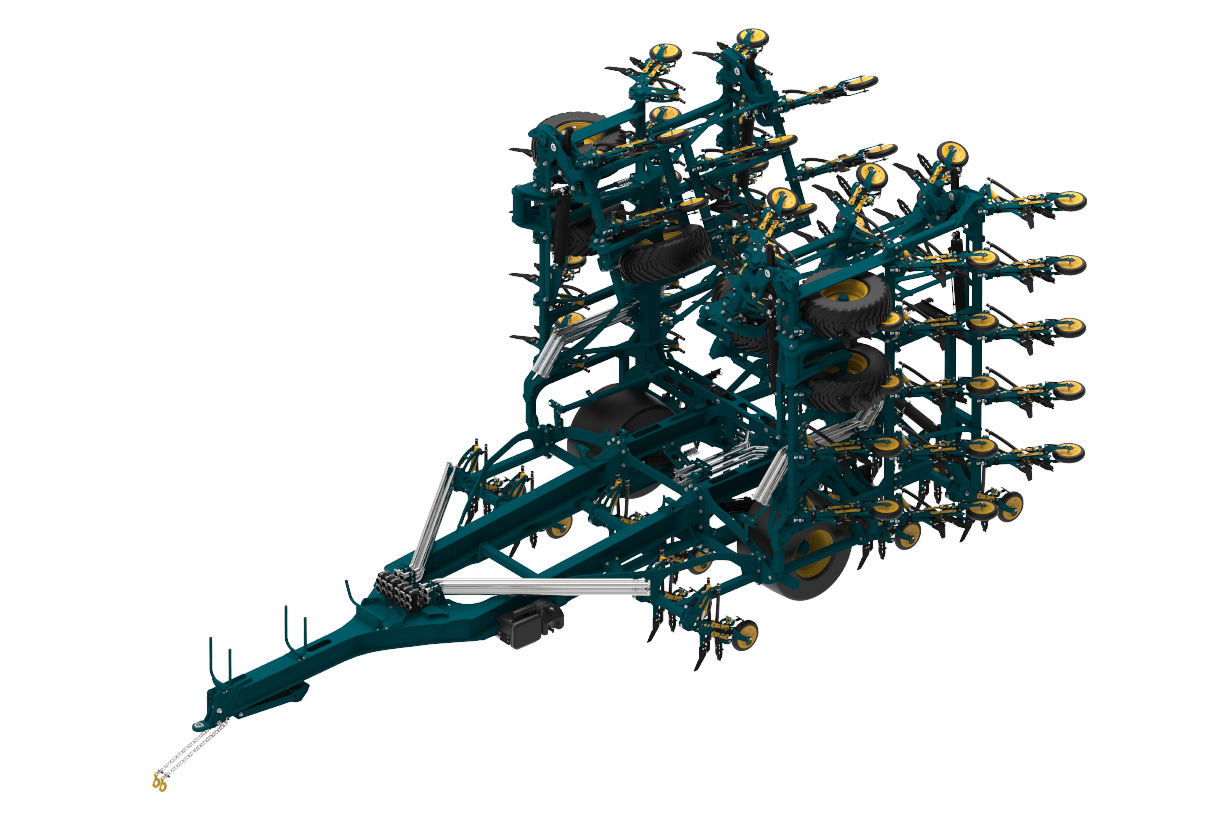

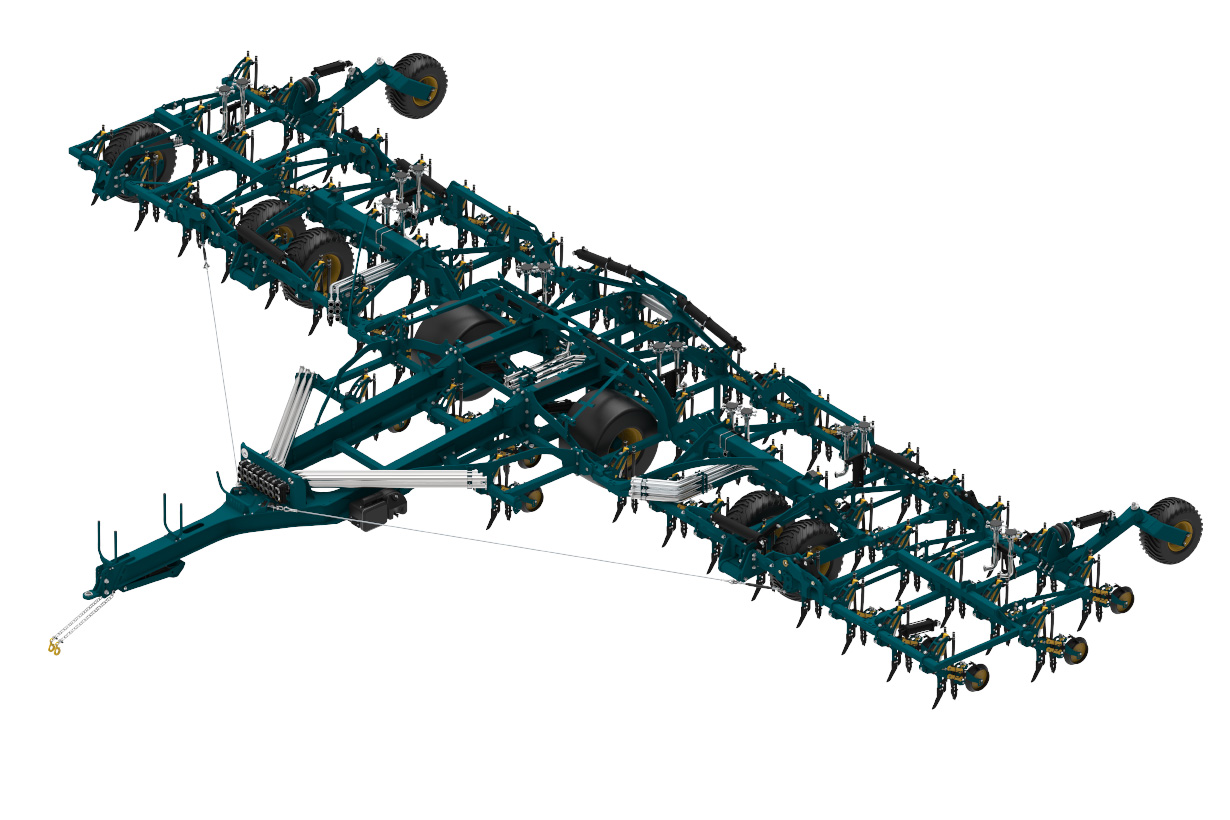

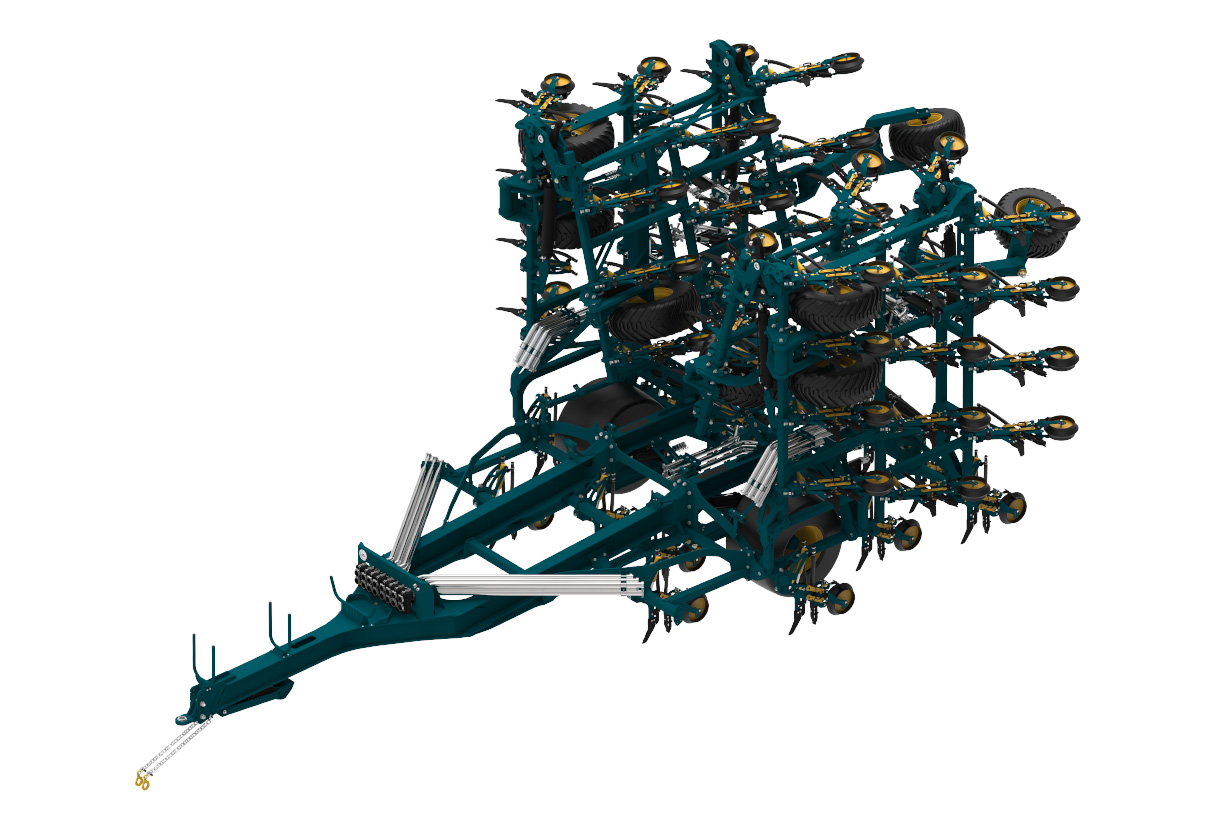

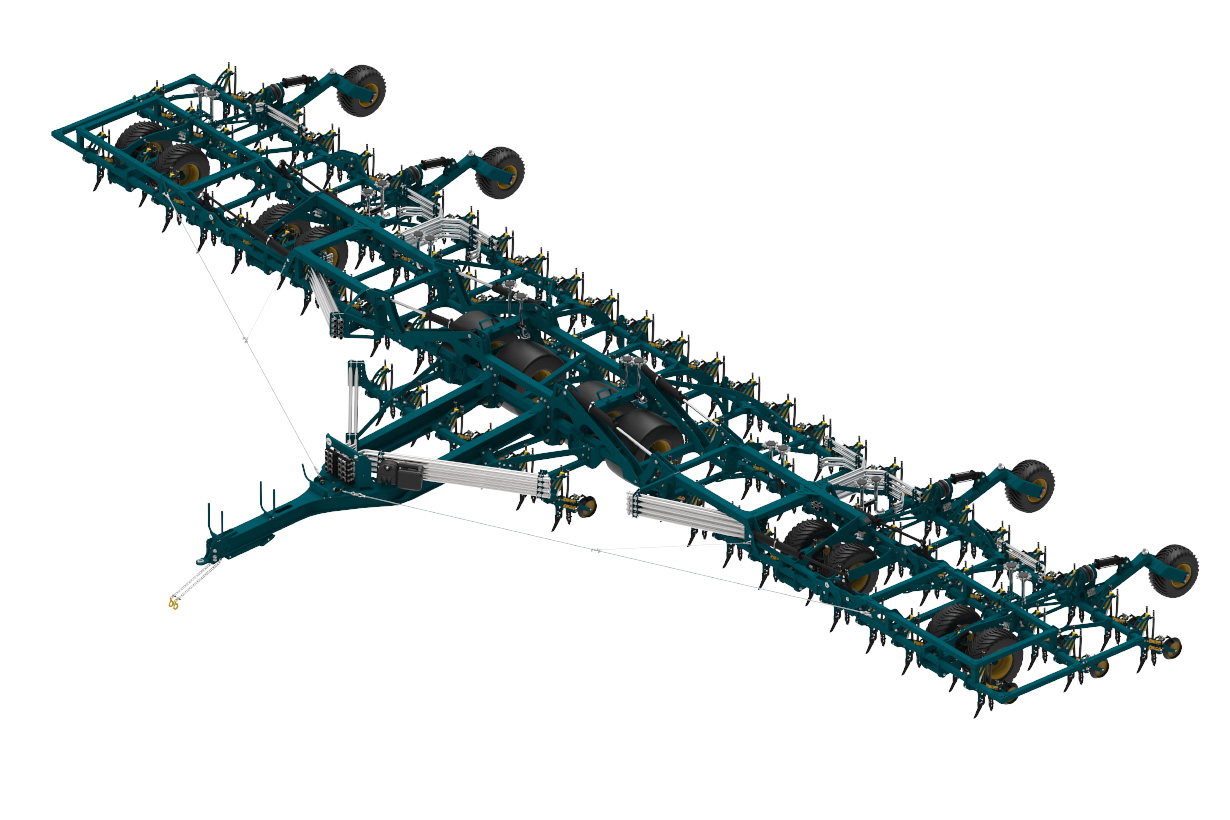

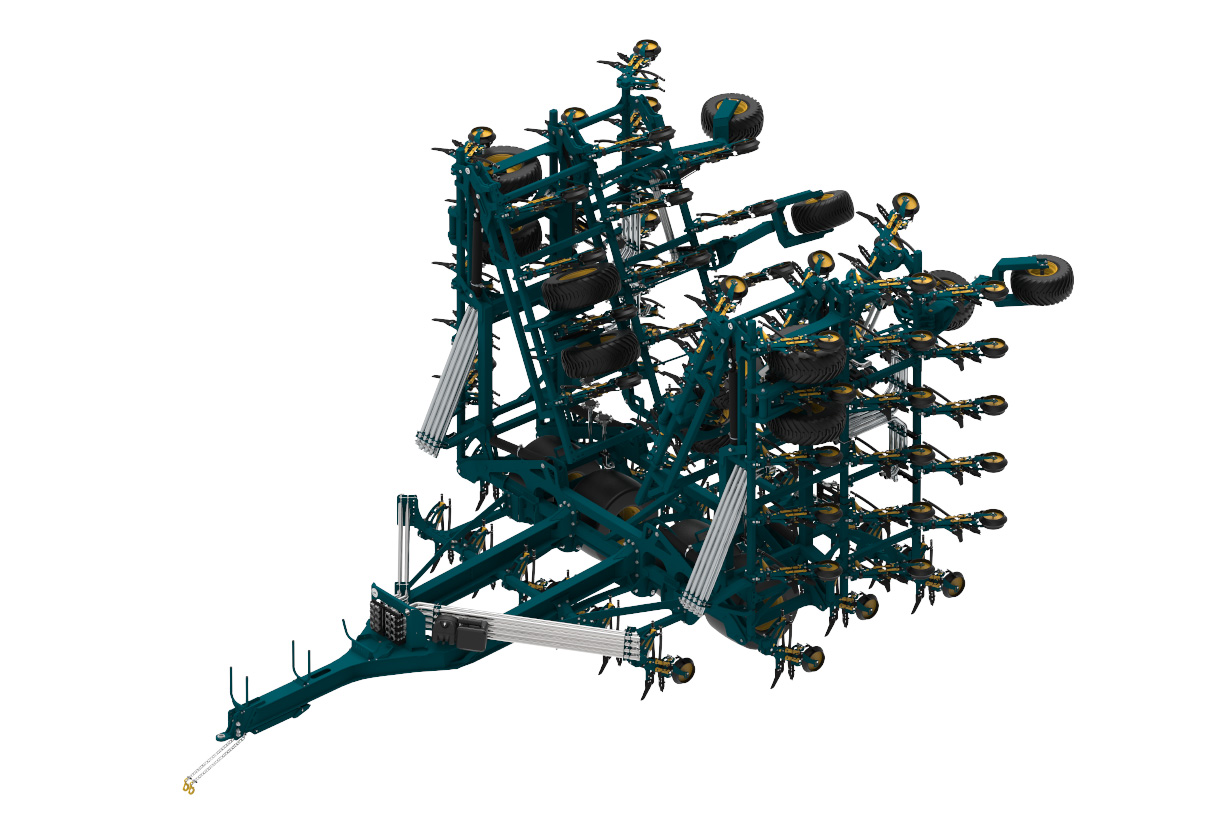

Tine Seeders(Drills)

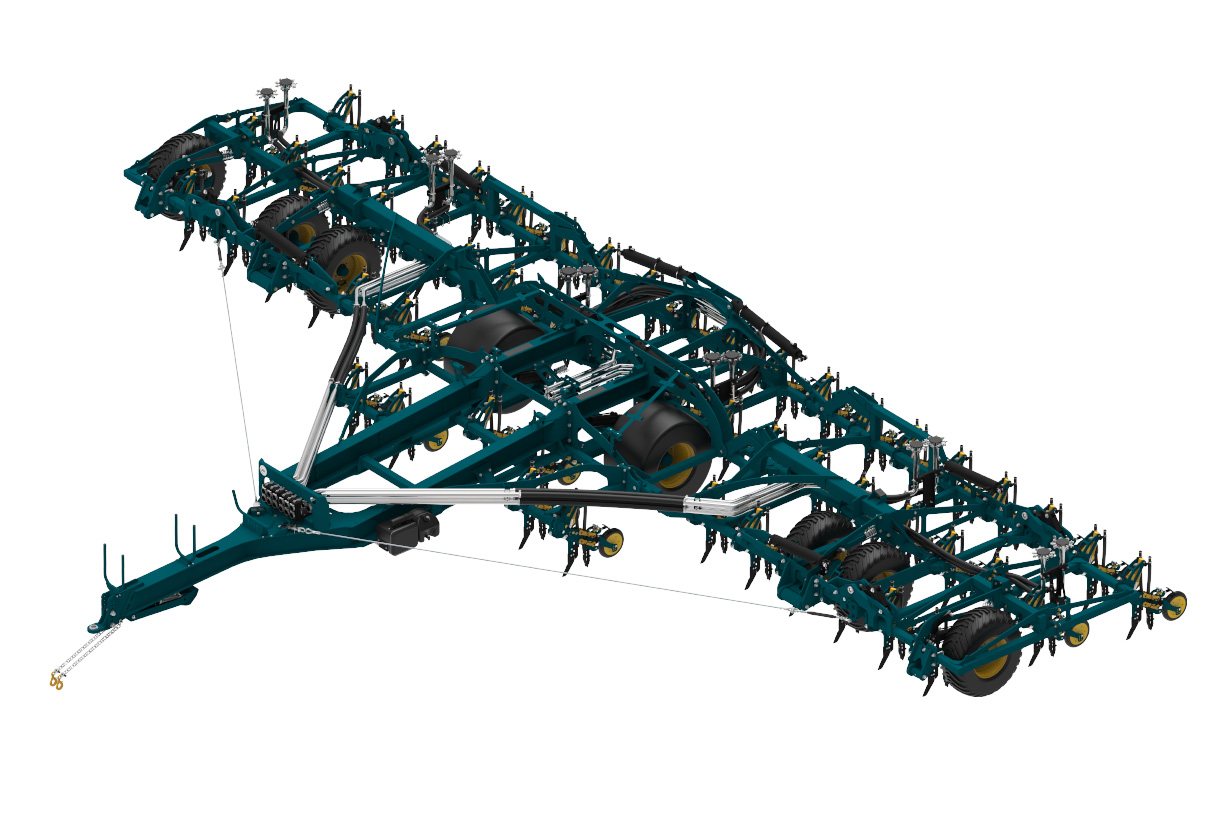

- Seeder sizes range from 40 to 80 rows, with row spacing options from 273mm and 300mm

- Minimum or reduced tillage

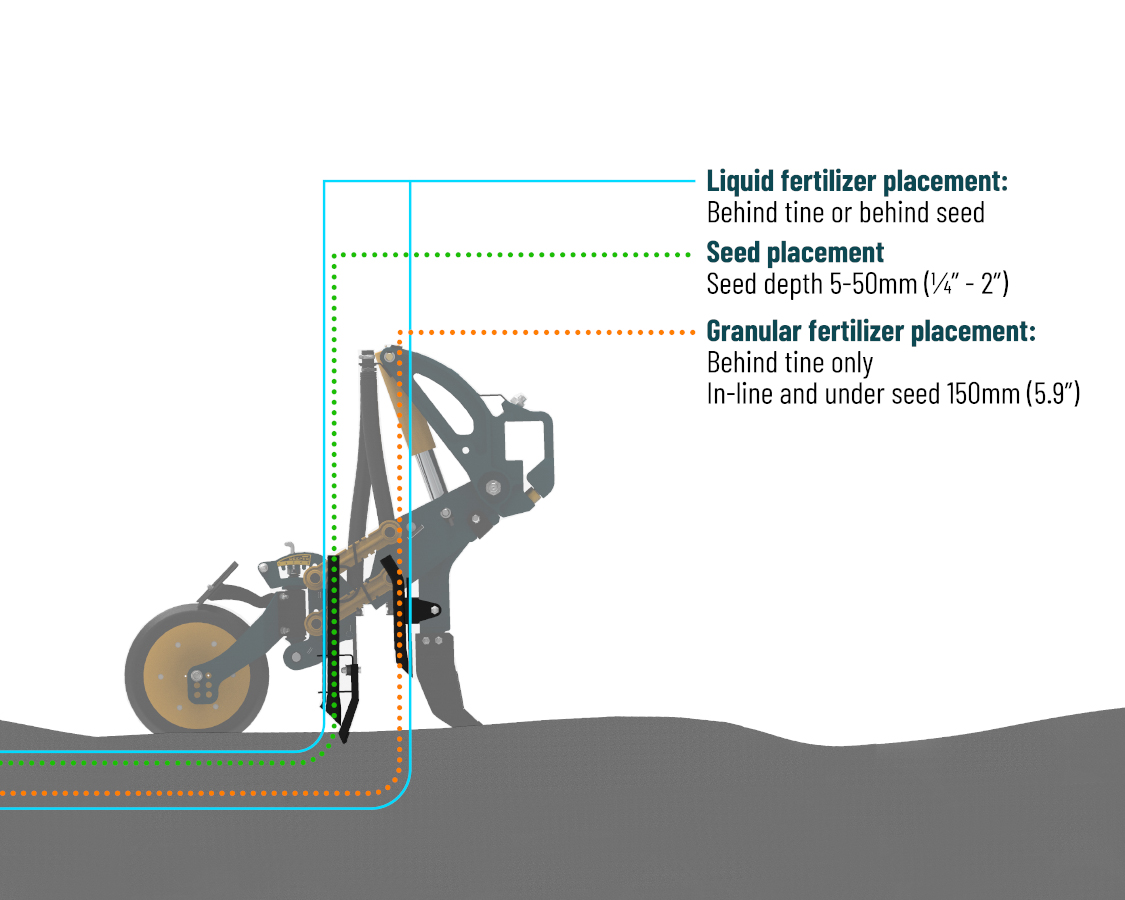

- Granular and liquid fertilizer options

The Tine Seeder(Drill) is a Min-Till seeder that can handle heavy residue and vertically band dry and/or liquid fertilizer directly below the seed to a range of depths to optimize soil and moisture conditions.

Vertical banding and uniform seed placement.

Tine Seeder(Drill) Benefits

- Robust, high-strength steel frame and row units are built to perform in tough conditions.

- On-frame hopper options available.

- Unit break-out force of 450kg (992lbs).

- Quick seed depth adjustment without any tools.

- 3m (120") main wheel track.

- The frame lifts high for easy maintenance from a standing position, eliminating the need to work on the floor.

Tine Seeders(Drills) Overview

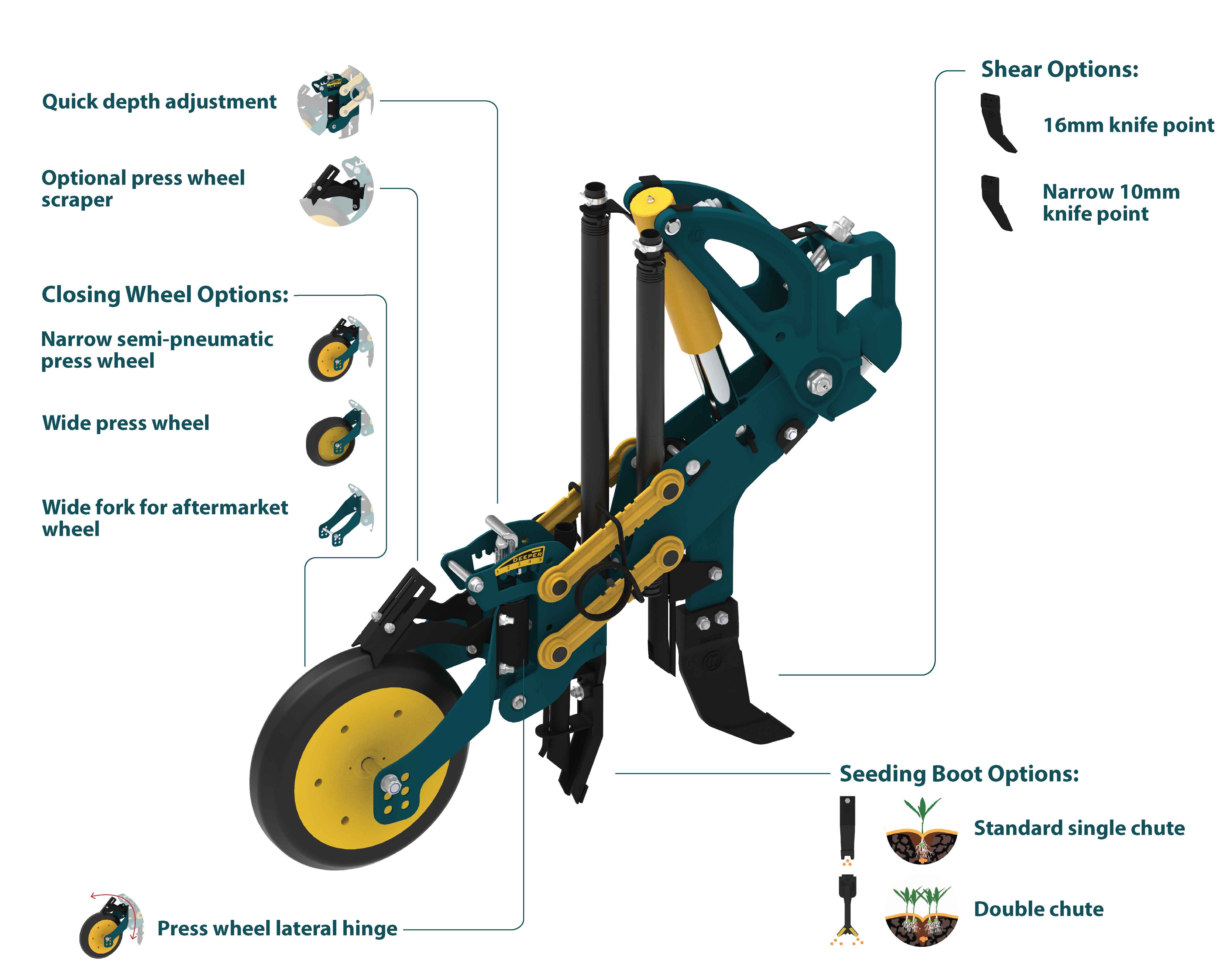

The Tine Seeder(Drill) Row Unit

Standard Unit Features

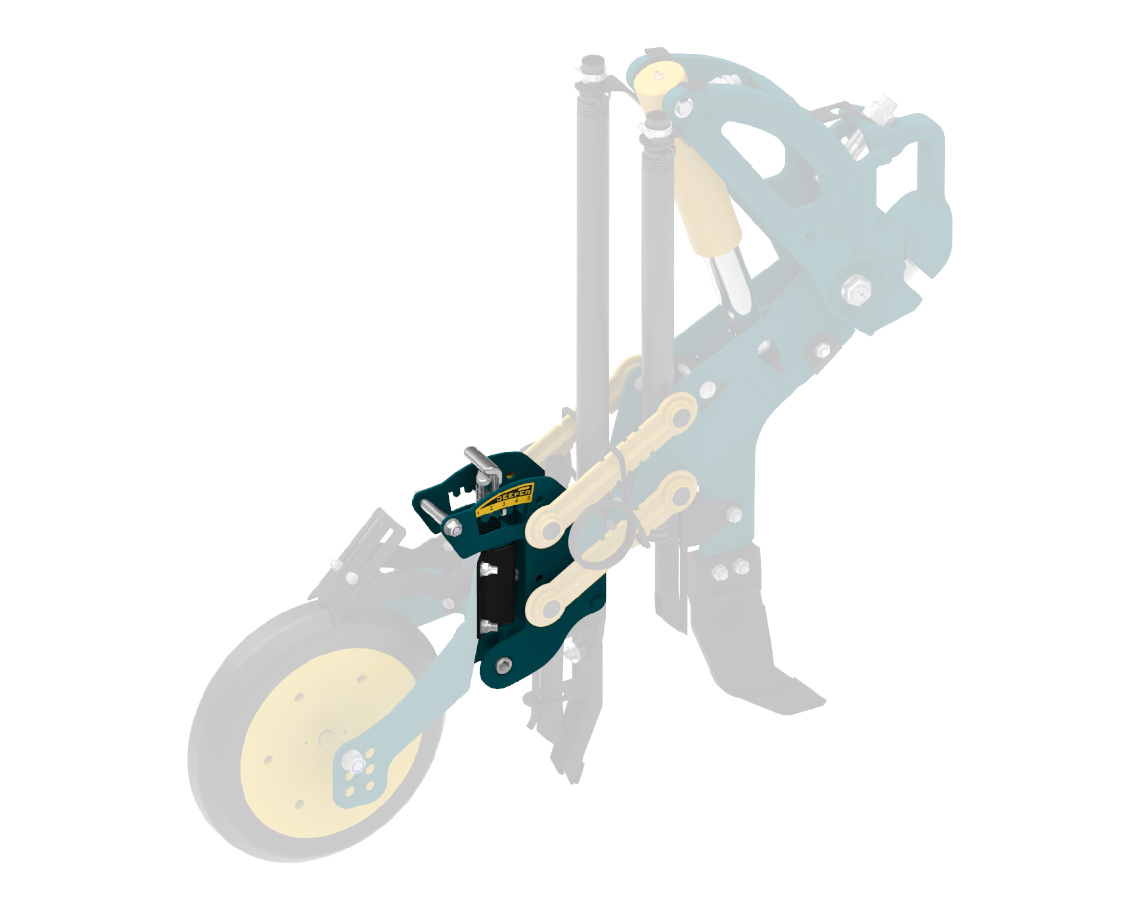

Quick and easy depth adjustment by hand.

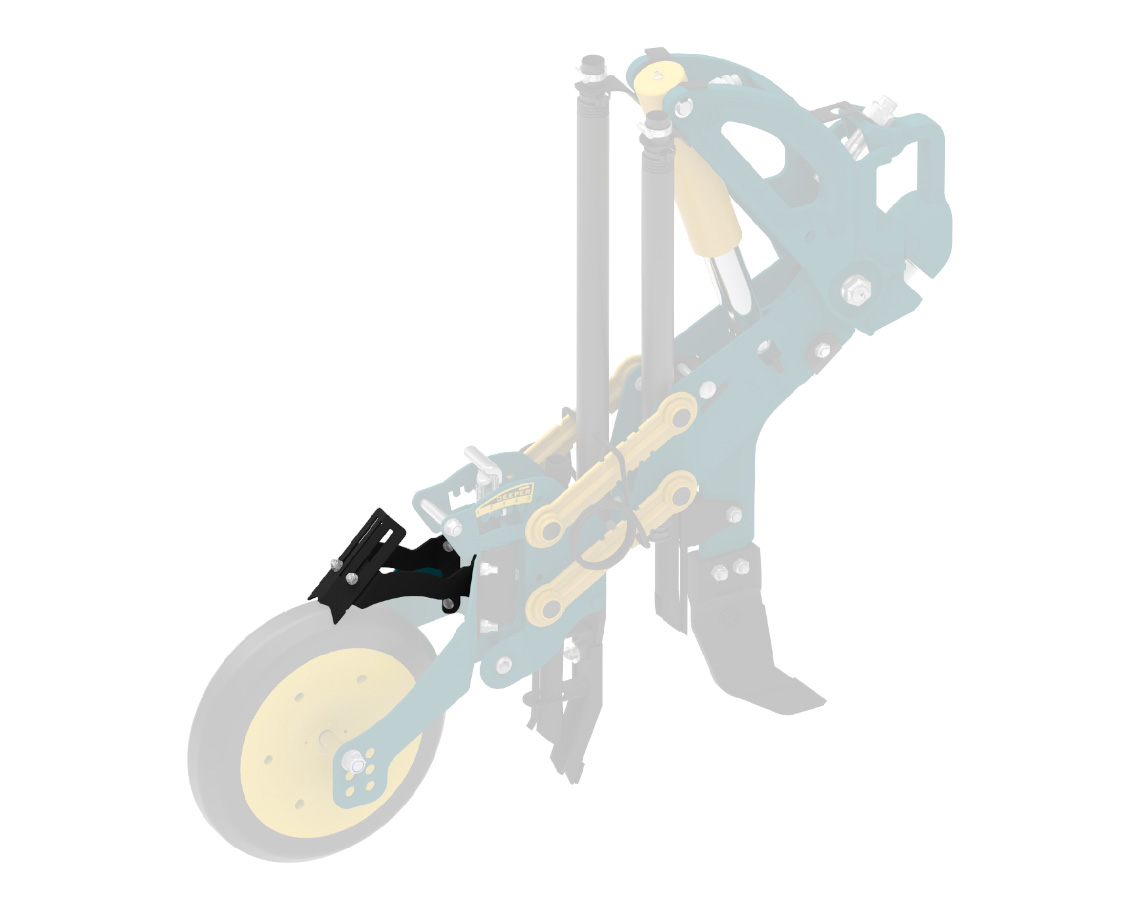

To remove mud build-up in sticky conditions.

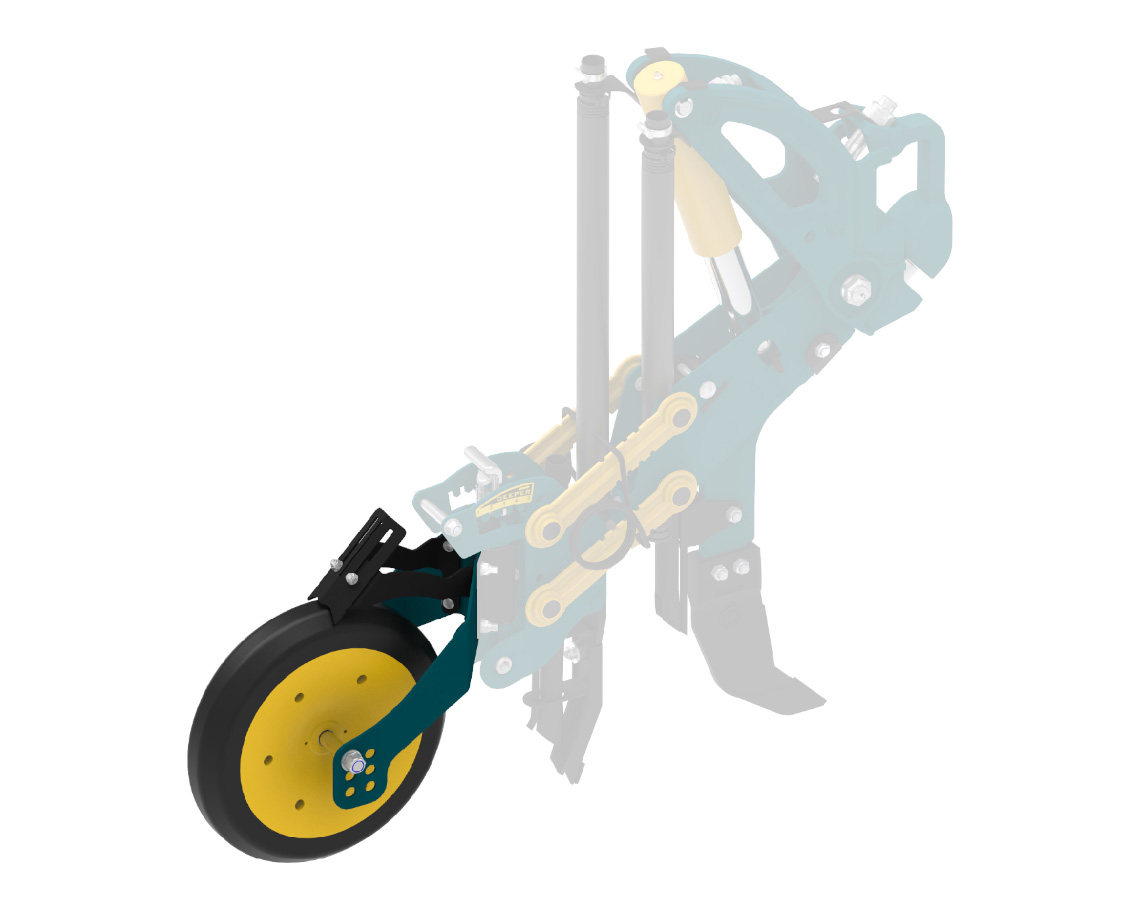

Narrow semi-pneumatic press wheel

Works well in rocky and most other conditions.

Wide EQUALIZER press wheel

Works well in very soft and sandy conditions.

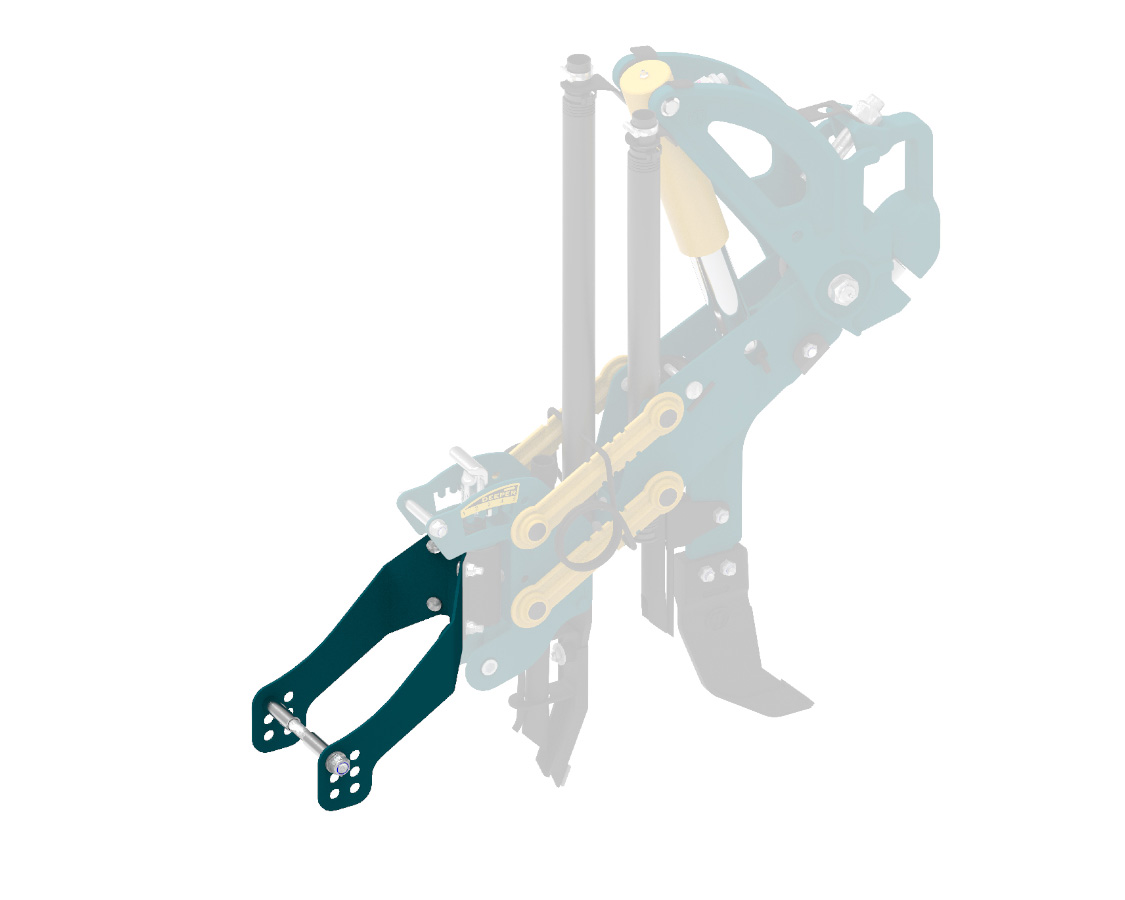

Wide fork for aftermarket wheel

Fork, bolt and spacers for when a unique aftermarket wheel is required.

Allows slight lateral movement to follow furrow around contours.

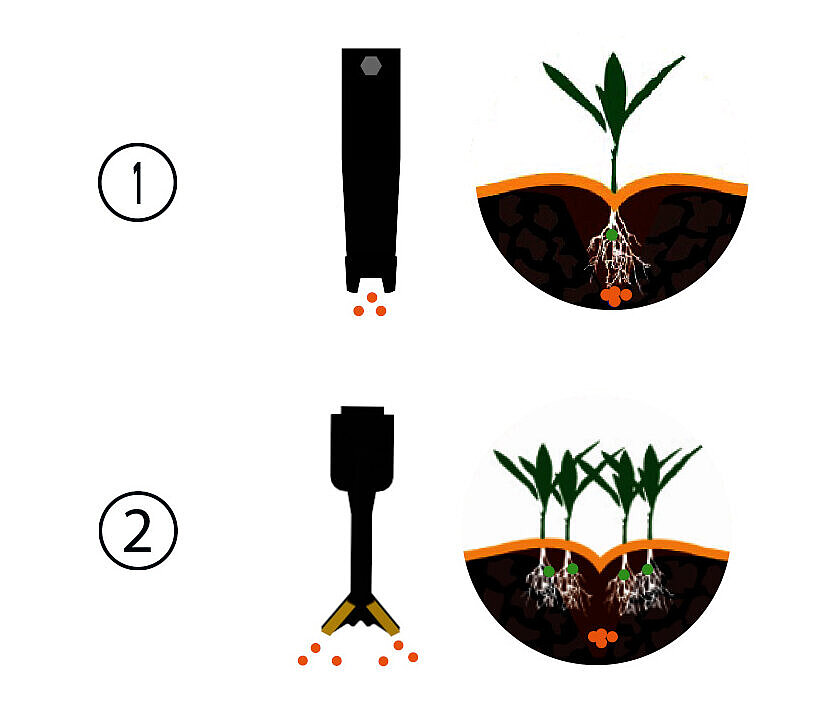

1. 16mm (5/8”) knife point

For extra durability and prolonged wear life.

2. Narrow 10mm (3/8”) knife point

Reduced or minimal soil disturbance.

1. Standard single chute

Seed depth 5-50mm (¼” - 2” )

Seed band width 30mm (1¼”)

2. Double chute

Seed depth 5-30mm (¼” - 1¼”)

Seed band width 60mm (2¼”)

Independent fertilizer & seed placement

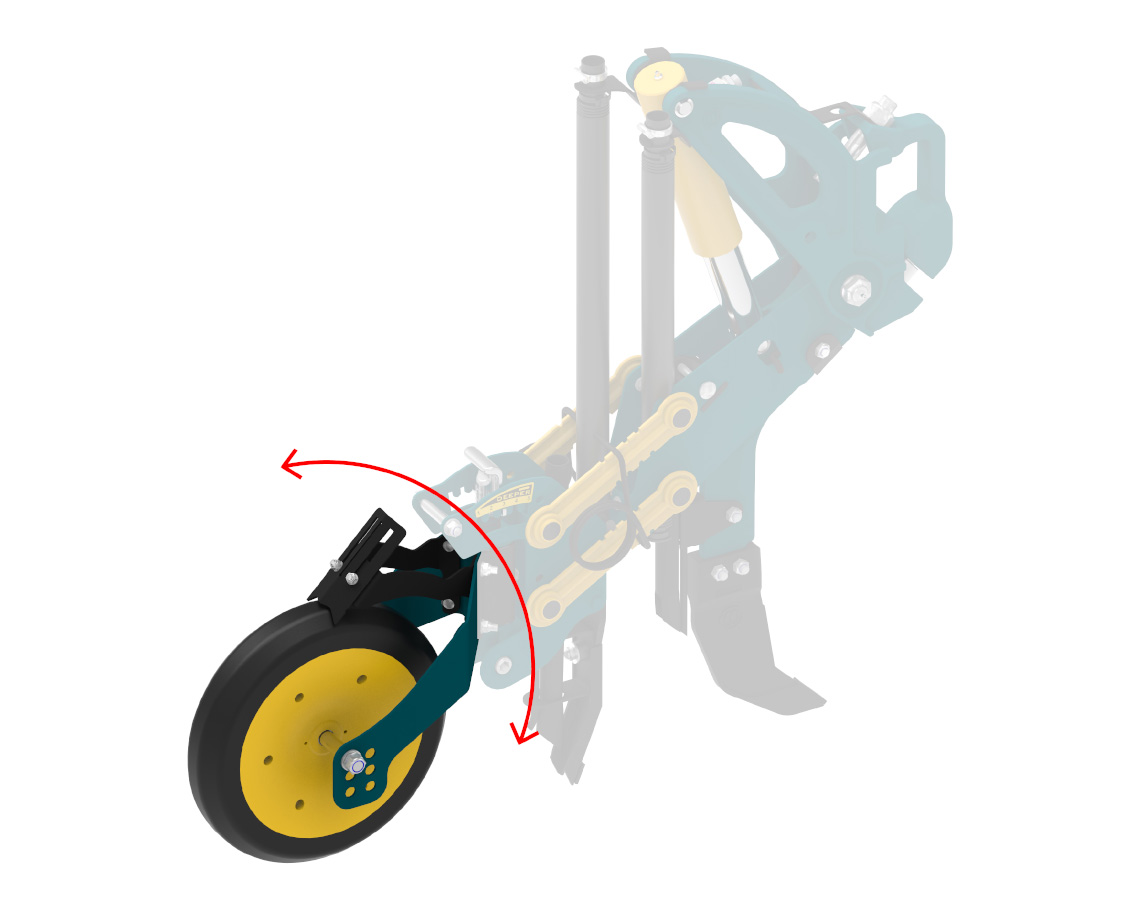

Optional hydraulic residue coulter

- Hydraulic cylinder for superior residue-cutting ability.

- Hydraulic downforce with easy adjustment, up to a maximum of 300kg (660lb).

- Hydraulic raise-and-store function for coulters when not in use.

- 560mm (22”) large cutting disc.

- Maintenance-free, sealed SKF Agri Hub bearing.

- Allows for lateral swing.

Product Range Specifications

Seeds: All small grains