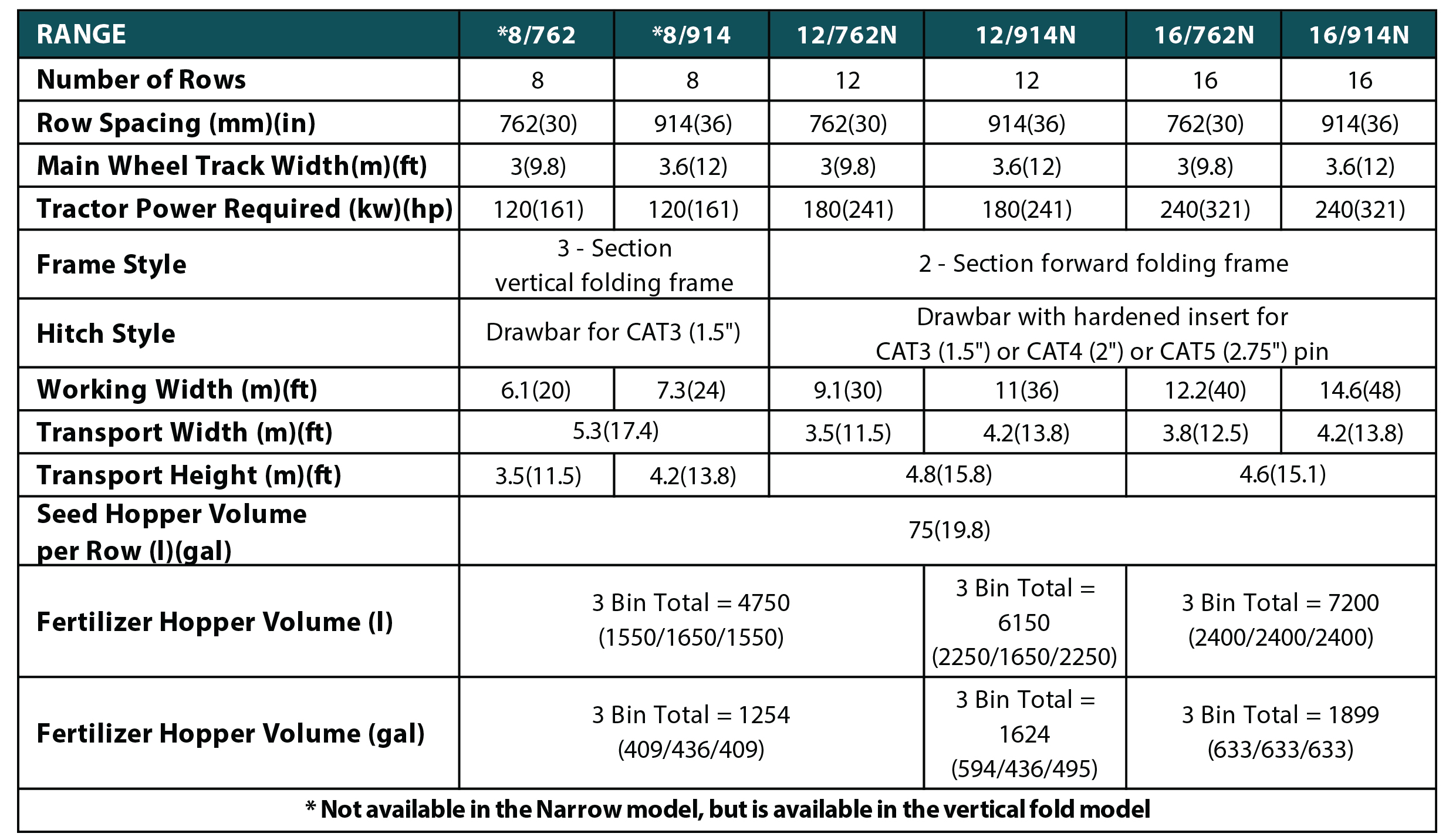

SLII Narrow Planters

- Planter sizes range from 8 to 16 rows, with row spacing options from 762mm to 914mm

- Conventional planter that can also work in moderate min-till conditions

- Granular and liquid fertilizer options

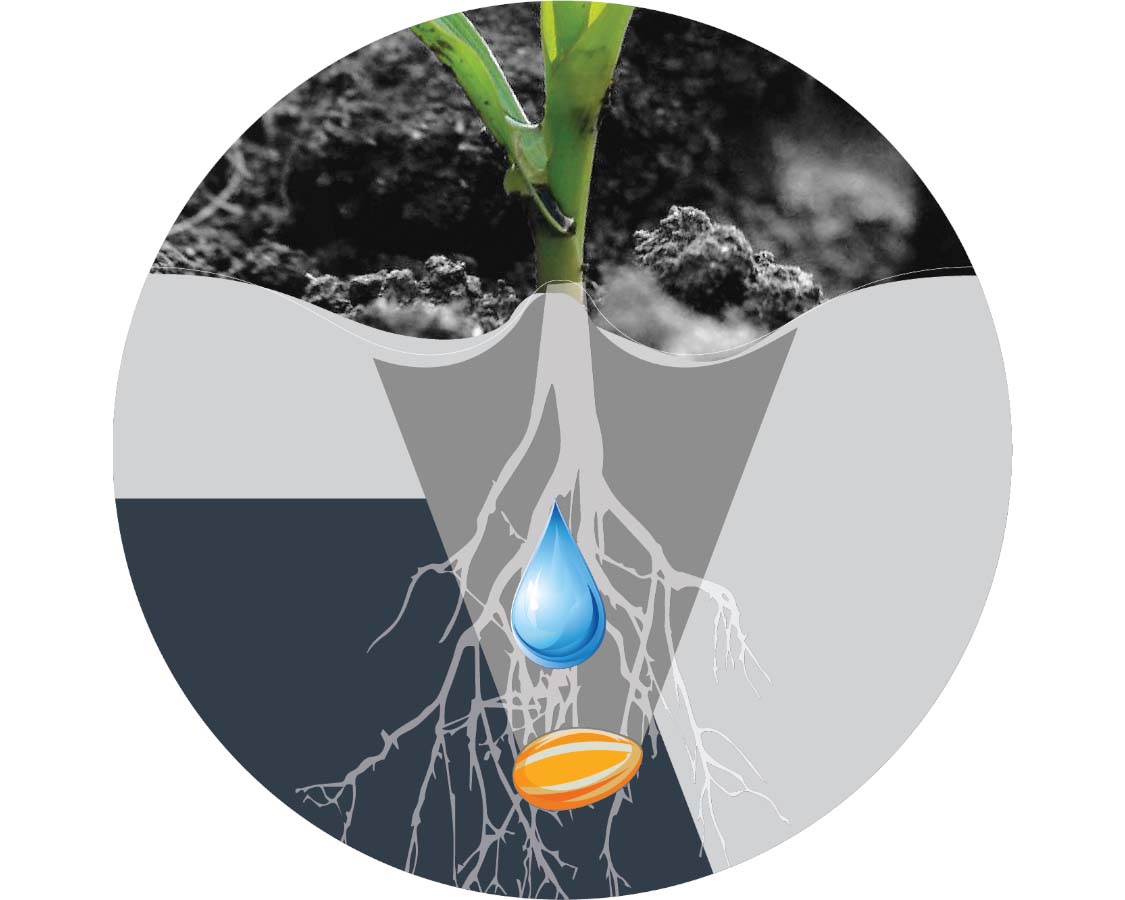

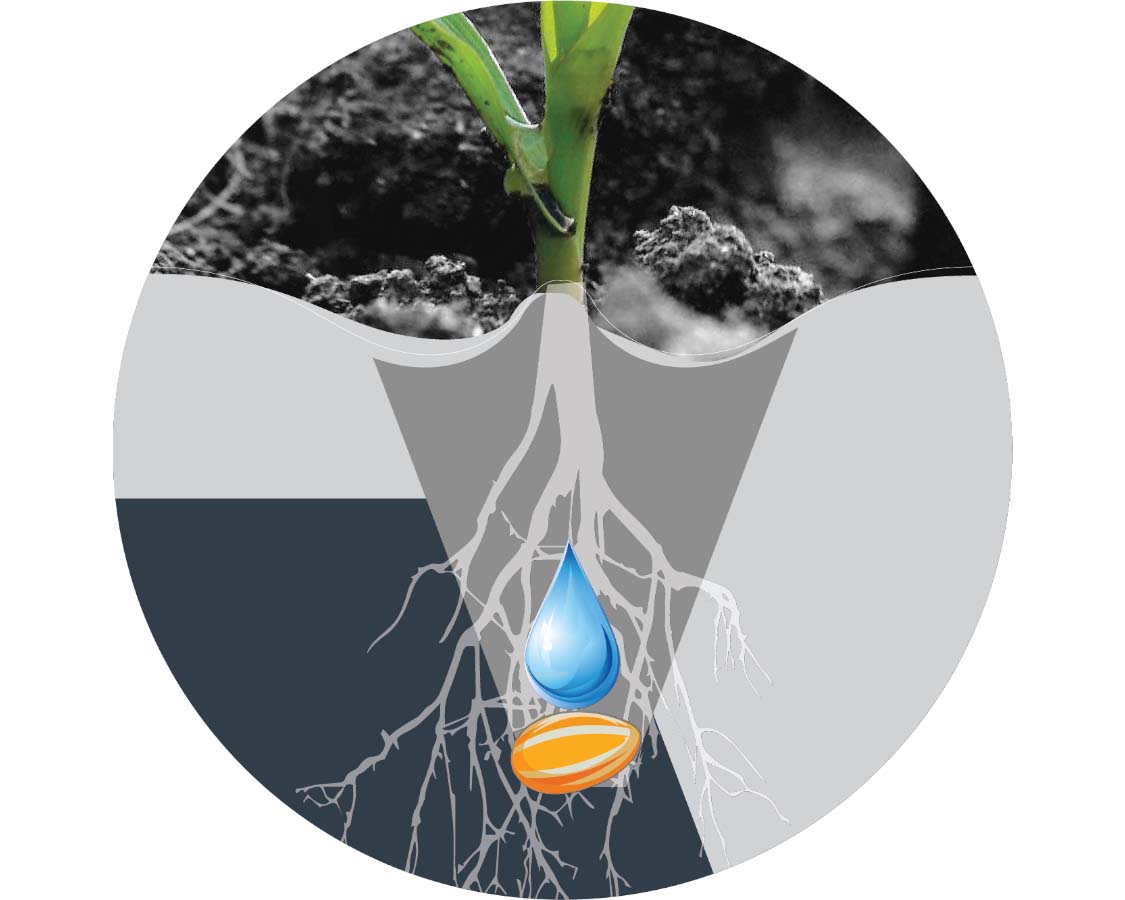

The SLII Narrow Planter combines precise, singulated seed placement with vertical banding of fertilizer. The unique combination of tine fertilizer delivery and planter seed delivery ensure both the seed and fertilizer are placed optimally. Ideal for minimal or reduced tillage, it ensures efficient planting in diverse field environments for planting crops such as corn, soybeans, sunflowers etc.

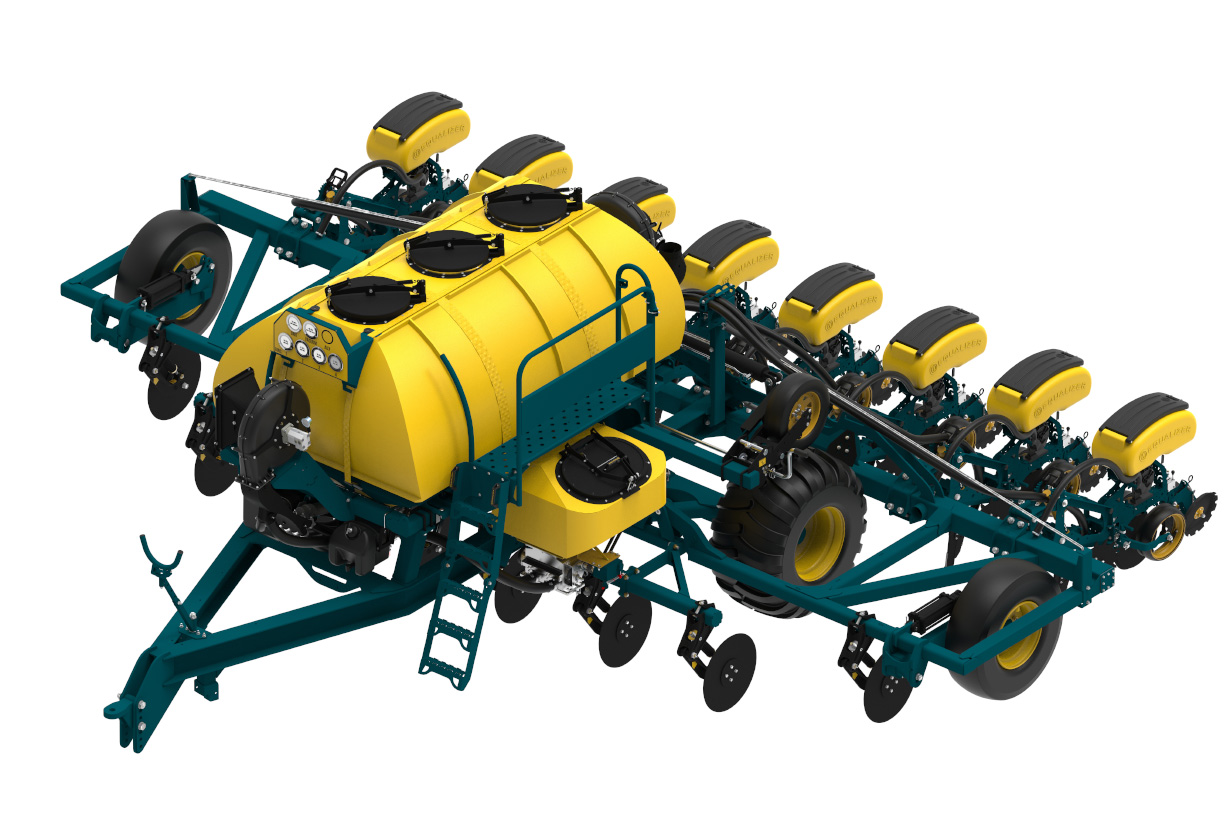

SLII Narrow Planter Benefits

- Robust, high-strength steel frame and row units are built to perform in tough conditions.

- Factory fitted on-frame tanks that offers granular or liquid fertilizer option and combinations of both.

- Factory fitted with Precision Planting™ equipment.

- The frame lifts high for easy maintenance from a standing position, eliminating the need to work on the floor.

- Narrow transport dimensions range from 3.5 m (11.5 ft) to 4.2 m (13.8 ft) in width and up to 4.8 m (15.8 ft) in height.

- Large wheels for superior flotation.

SLII Narrow Planters Overview

Product Range

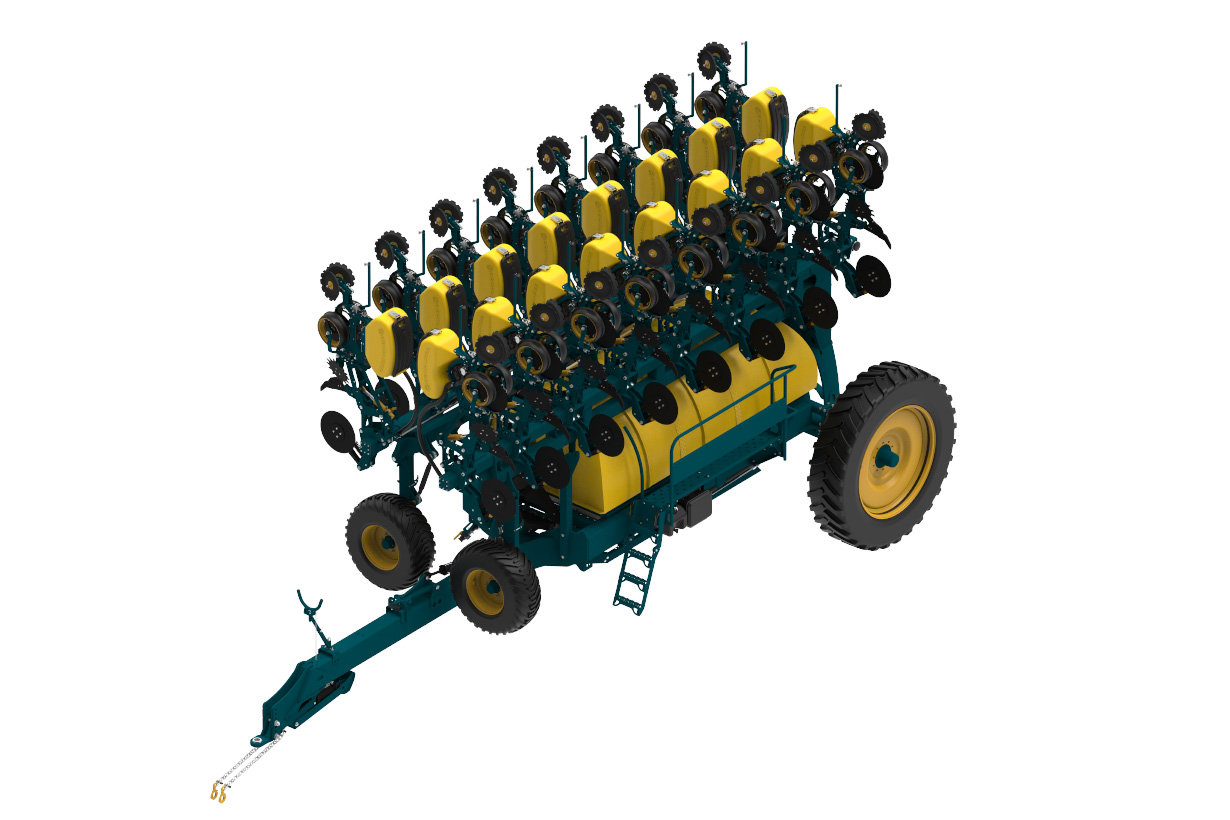

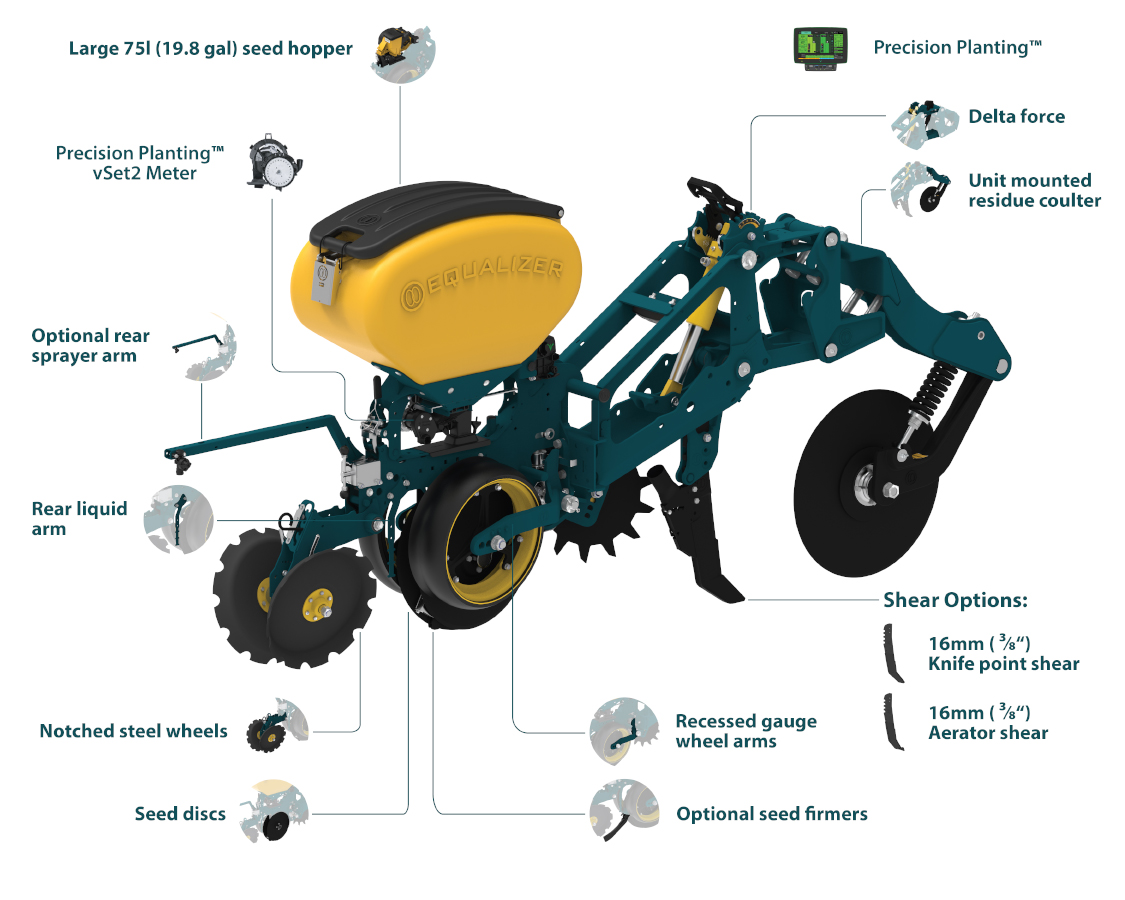

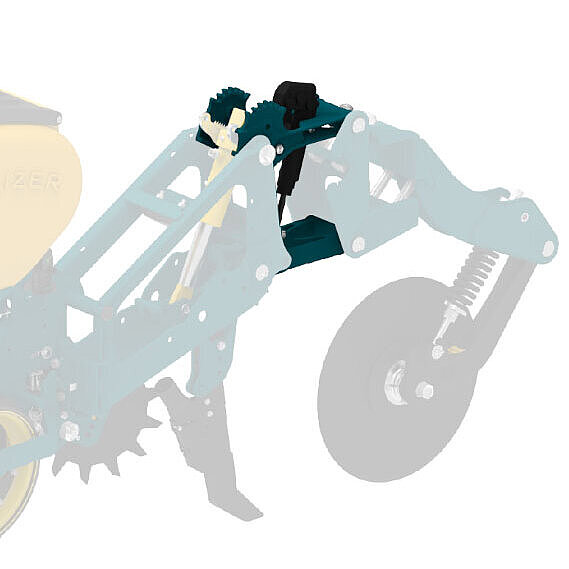

The SLII Precision Unit

Standard Unit Features

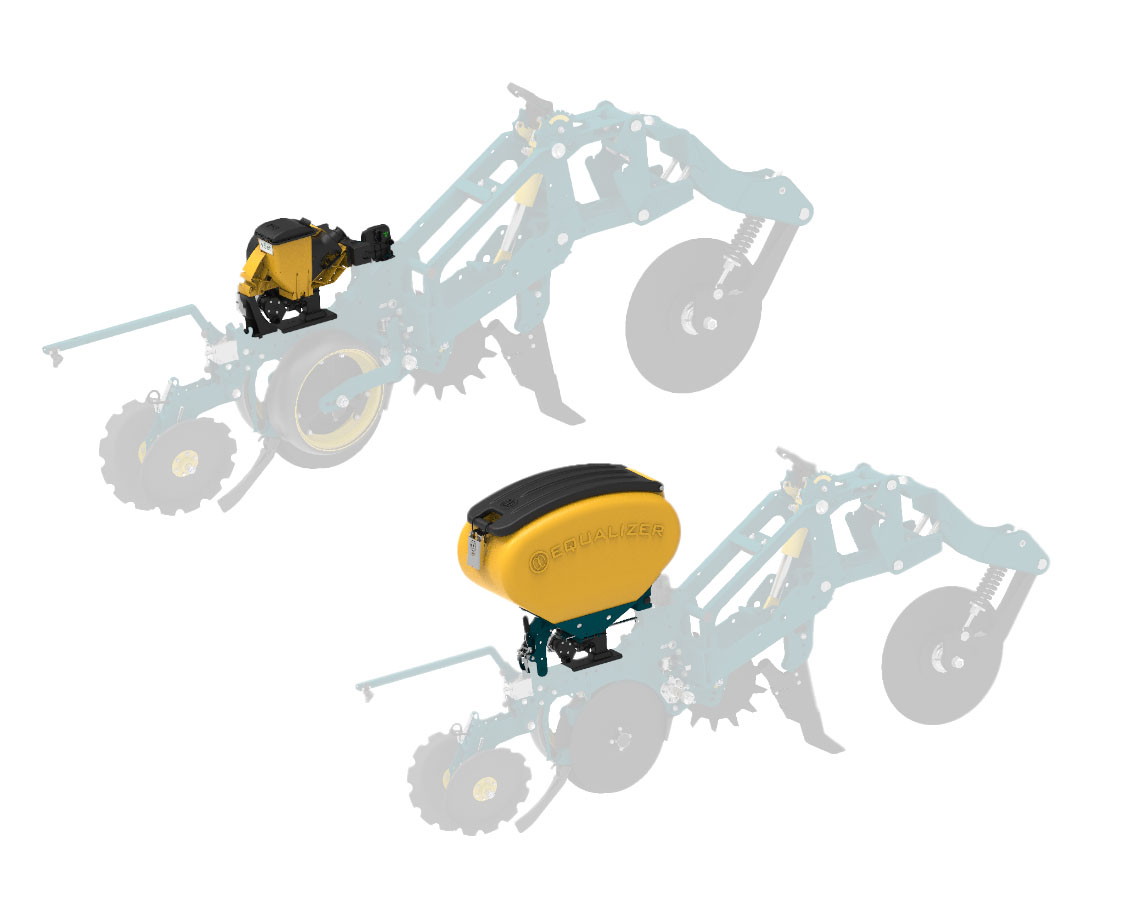

Large 75L (19.8 gal) Seed Hopper or Mini Hopper fed from a central seed hopper tank.

Factory-fitted with Precision Planting™ vSet2 for effortless meter accuracy. More than 13 crop kits to handle almost any crop, including maize, sunflower, soybeans, sugar beets etc.

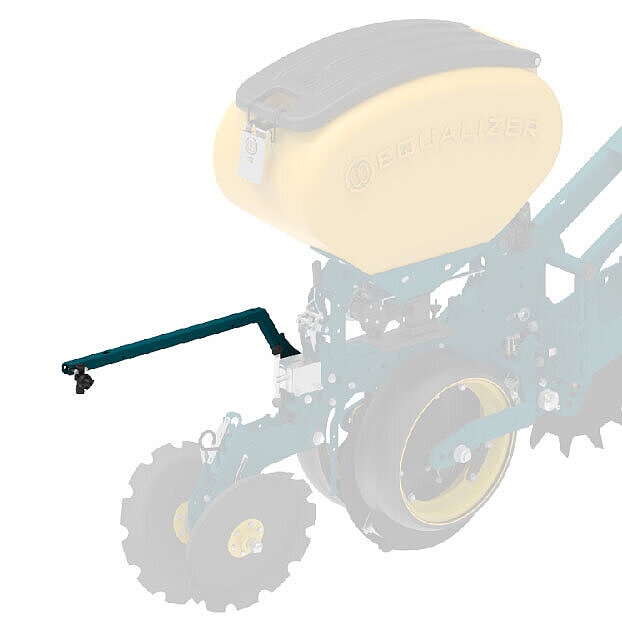

Herbicide application with a sprayer nozzle.

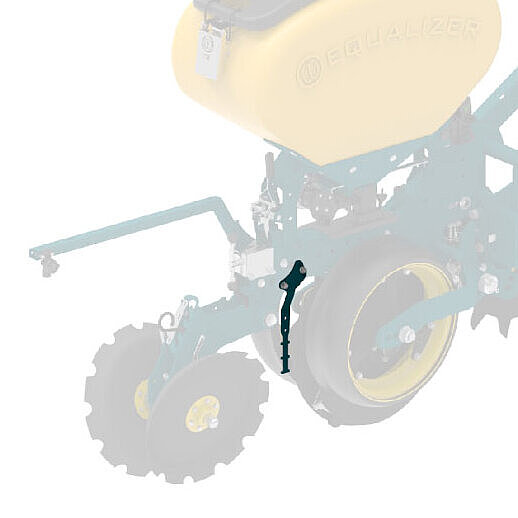

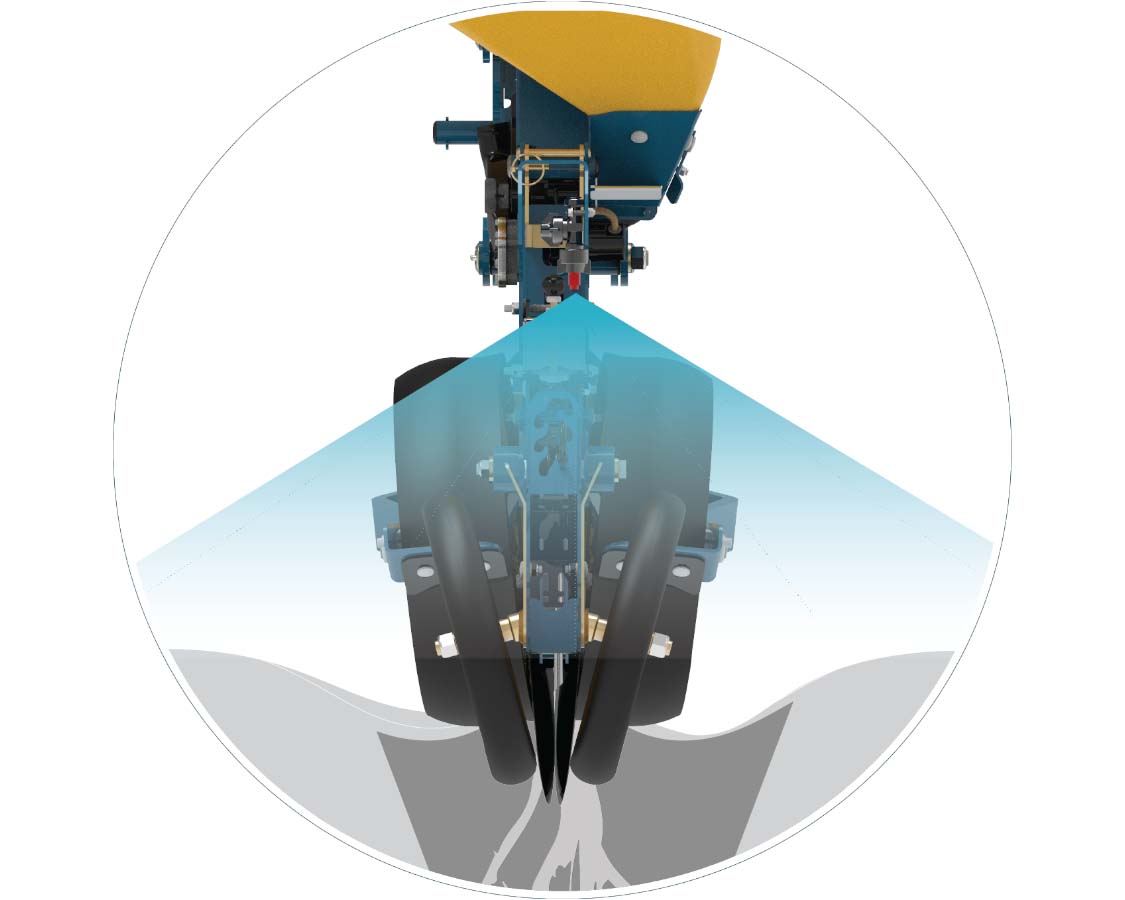

Liquid fertilizer or inoculant placement above the seed.

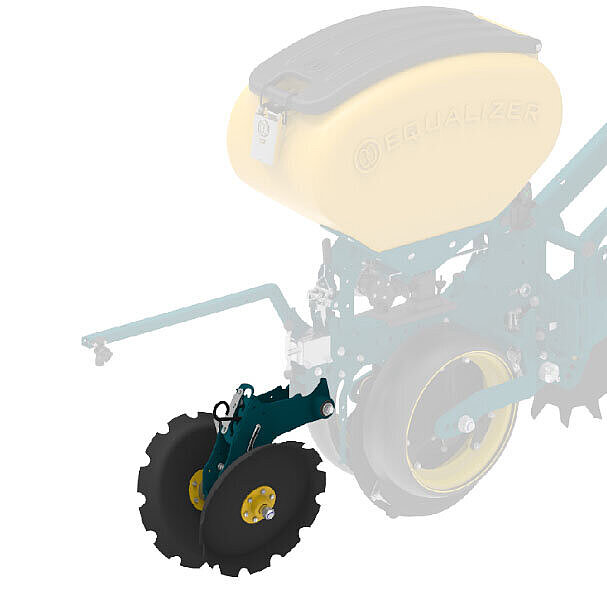

Notched steel closing wheels with independent toe-out adjustment.

Can be replaced without removing the hubs. 9.5-degree seed disc angle for less soil disturbance and better fuel efficiency.

Reduce the unit width and improve material flow.

Smart Firmer 2 compatible quick attach bracket or Low-Stick Keeton seed firmer with quick attach bracket.

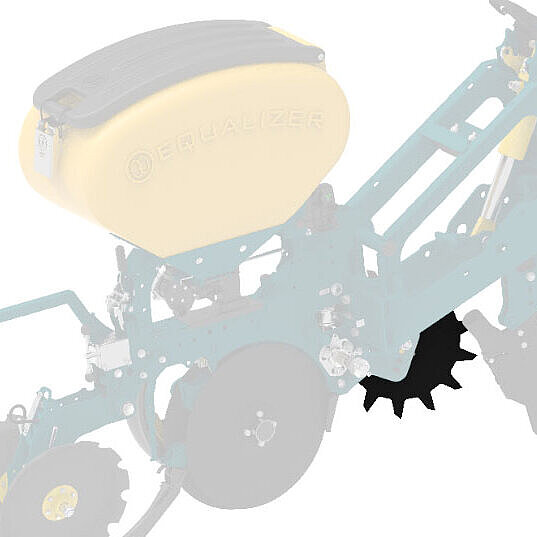

1. 16mm (3/8") Knife point shear

For extra durability and prolonged wear life.

2. 16mm (3/8") Aerator shear

For more aggressive aeration of the soil.

Single Row Cleaner.

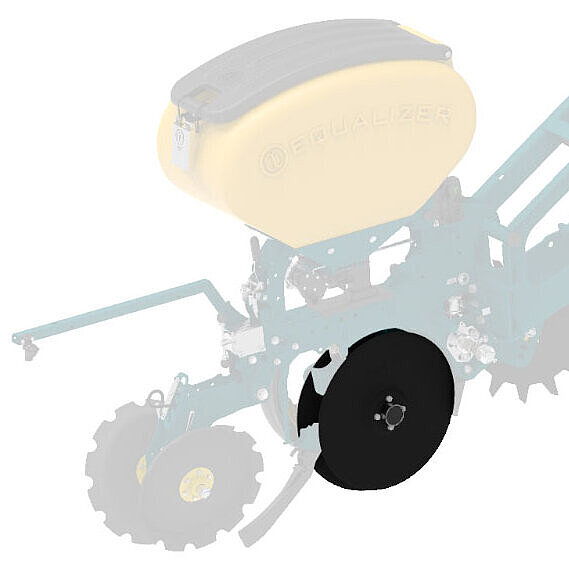

508mm (20"") coulter fitted on the frame in front of the unit.

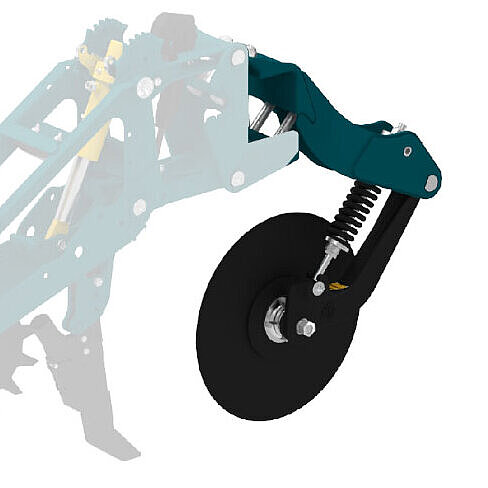

Easily adjustable mechanical spring downforce,

or Precision Planting™ DeltaForce(variable row-by-row hydraulic downforce).

Precision Planting™ 20/20 Gen3 SeedSense® monitor system.

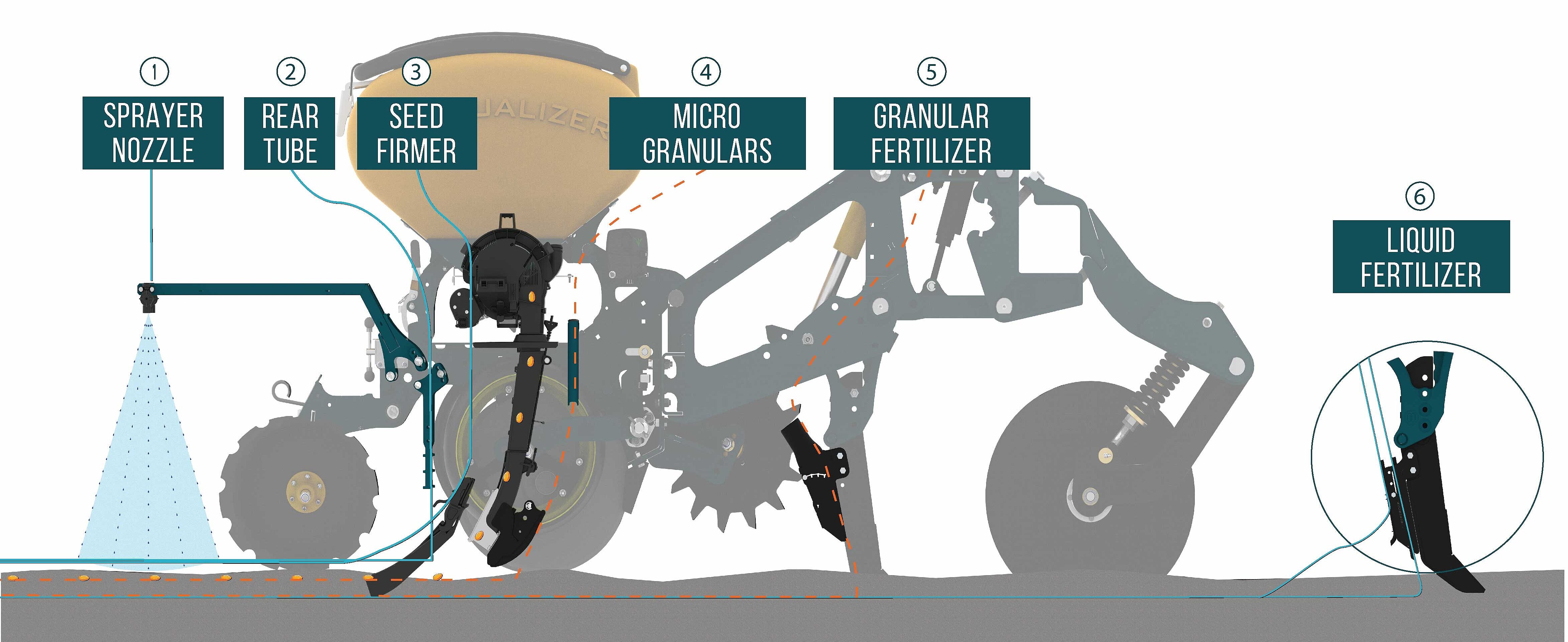

Product Placement

Placement Options

Herbicides application with a sprayer nozzle.

Liquid fertilizer or inoculant placement above the seed.

Liquid fertilizer or liquid inoculant placement on top of the seed.

Microgranular placement under seed.

Granular and/or liquid fertilizer placement 45mm (2 inches) next to and below the seed.

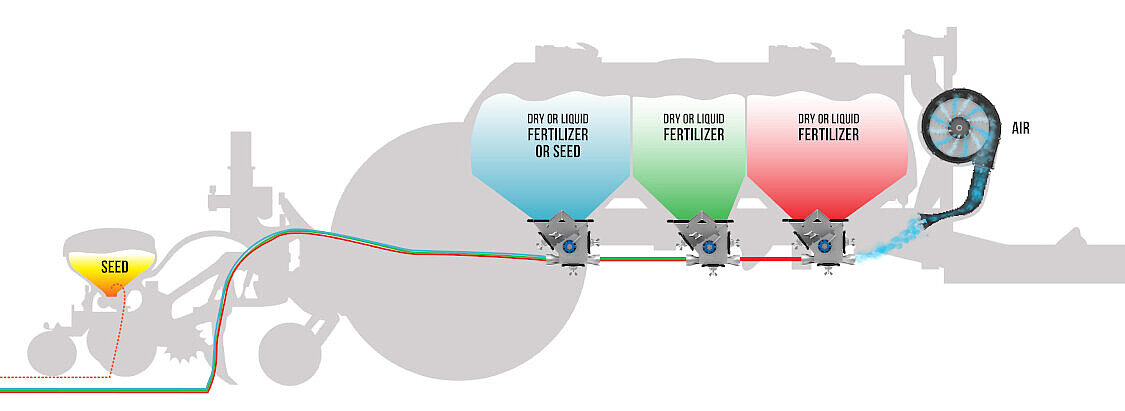

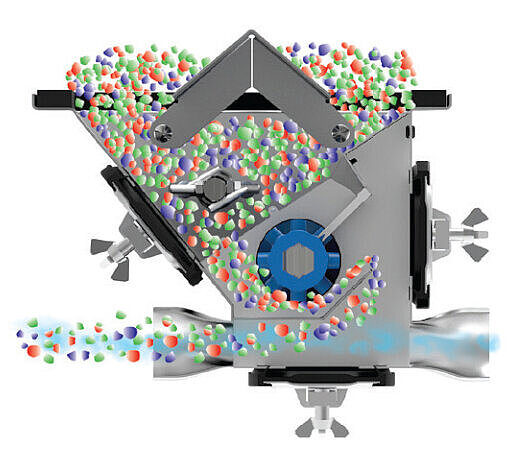

Seed & Fertilizer Distribution

- The polyethylene tanks are suitable for both liquid and granular fertilizers

- When equipped with liquid tanks, Banjo tank fittings, manifolds, valves, and three-stage filters are standard

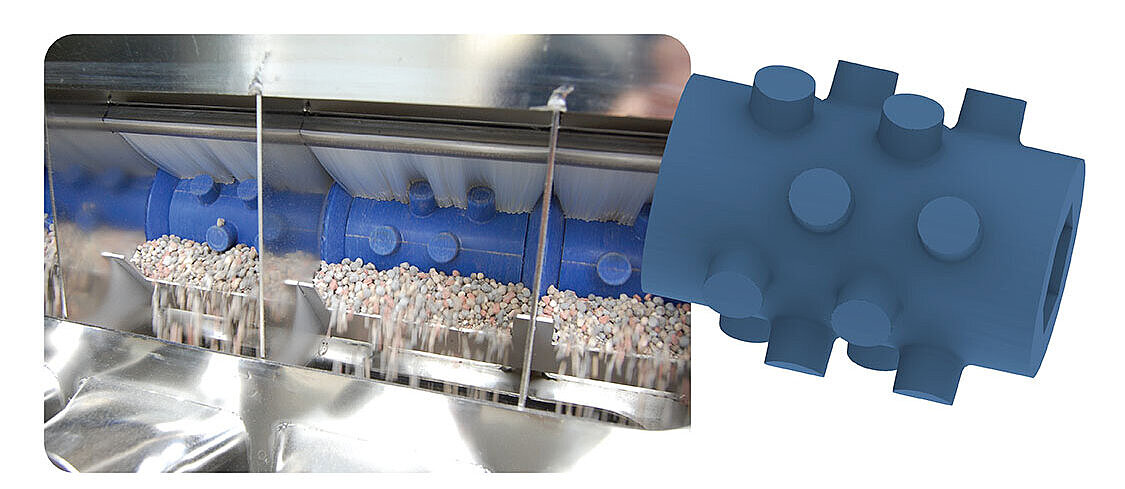

Granular Fertilizer Meterbox

- Stainless steel with self-cleaning poly meter roller

- Accurate, versatile and simple with effortless calibration

- One metering roller for all Fertilizer & Seed types and sizes

No roller changes required

Stainless steel metering units with individual line metering. This means each divider head has its own individual meter roller and there is only one divider head between the row unit and the metering roller which ensures maximum accuracy with an air seeder as eliminates the possibility of variation between sections.

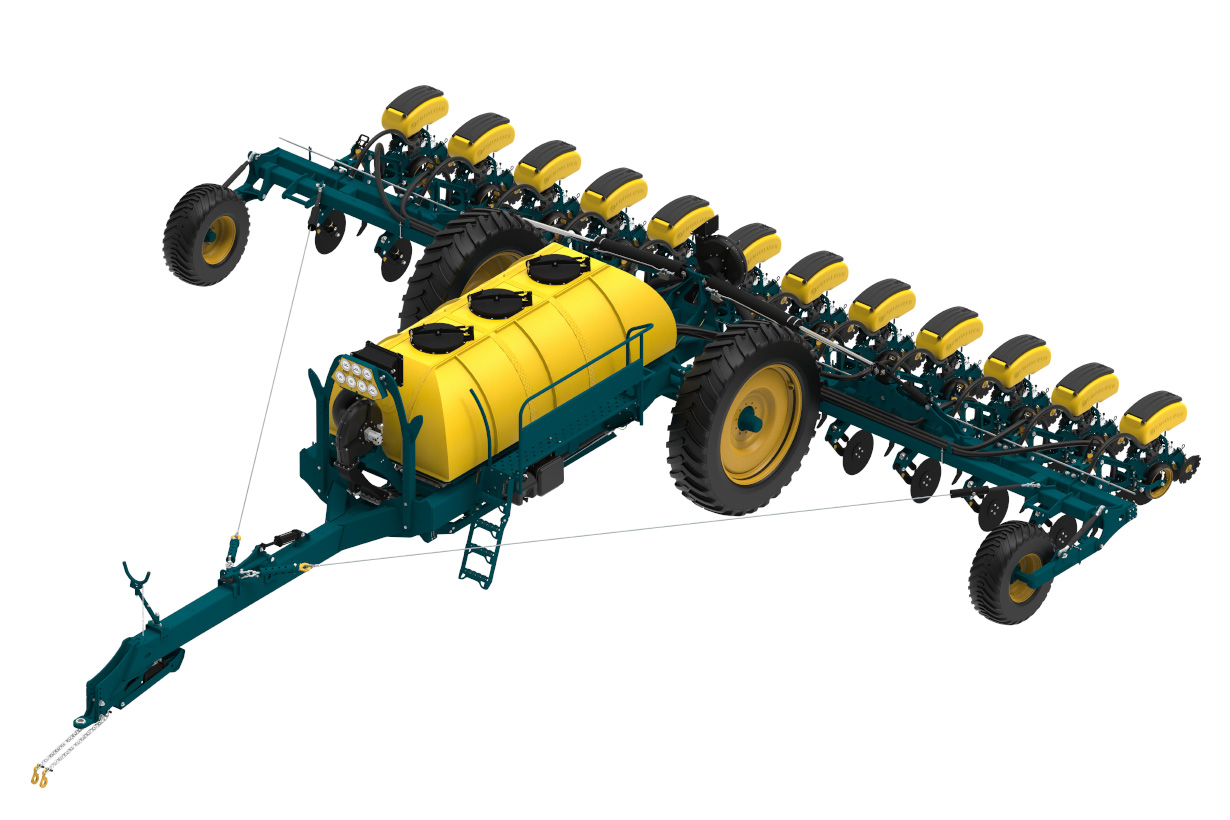

South Africa Product Range Specifications

*Specifications for planters delivered within South Africa